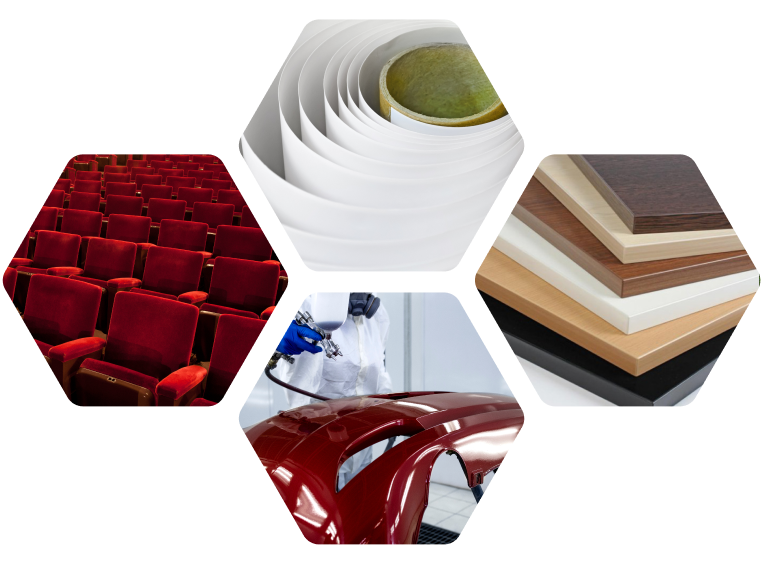

Unleashing the power of Urea. The flexible product that revolutionizes industries

Explore the transformative applications of melamine in modern industries. From durable laminates to heat-resistant coatings, melamine’s robust properties contribute to enhancing product quality and performance across various sectors.