HOW WE DO IT

Life cycle approach.

Support at different levels

In Casale, our customers find a trustworthy and competent partner, offering technical advice and continuous support throughout the project lifecycle. With our one-stop-shop approach, you benefit from a single point of contact and full project responsibility throughout. This streamlined process ensures a focus on excellence, efficiency, and an unwavering commitment to customer satisfaction.

Licensing &

Design

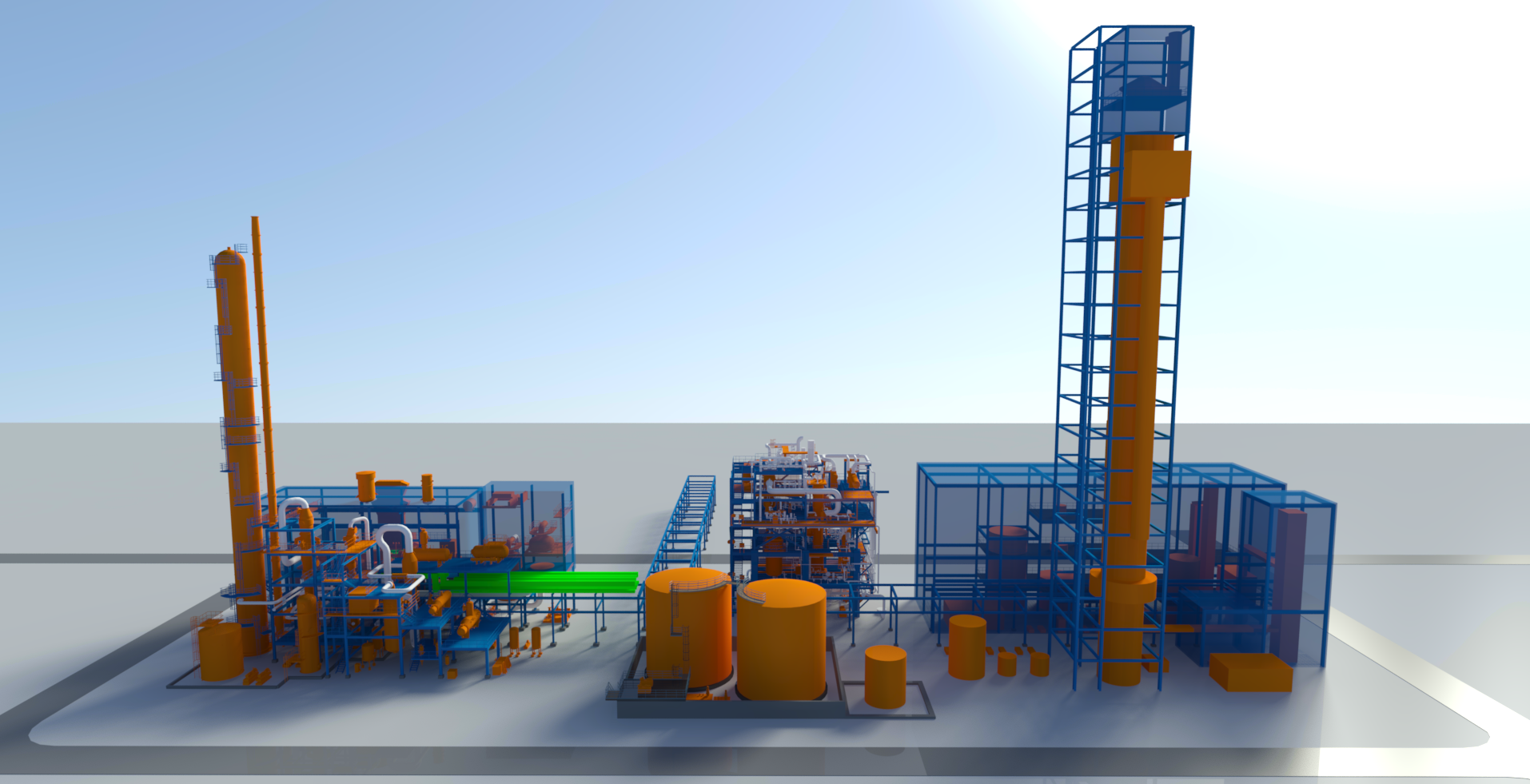

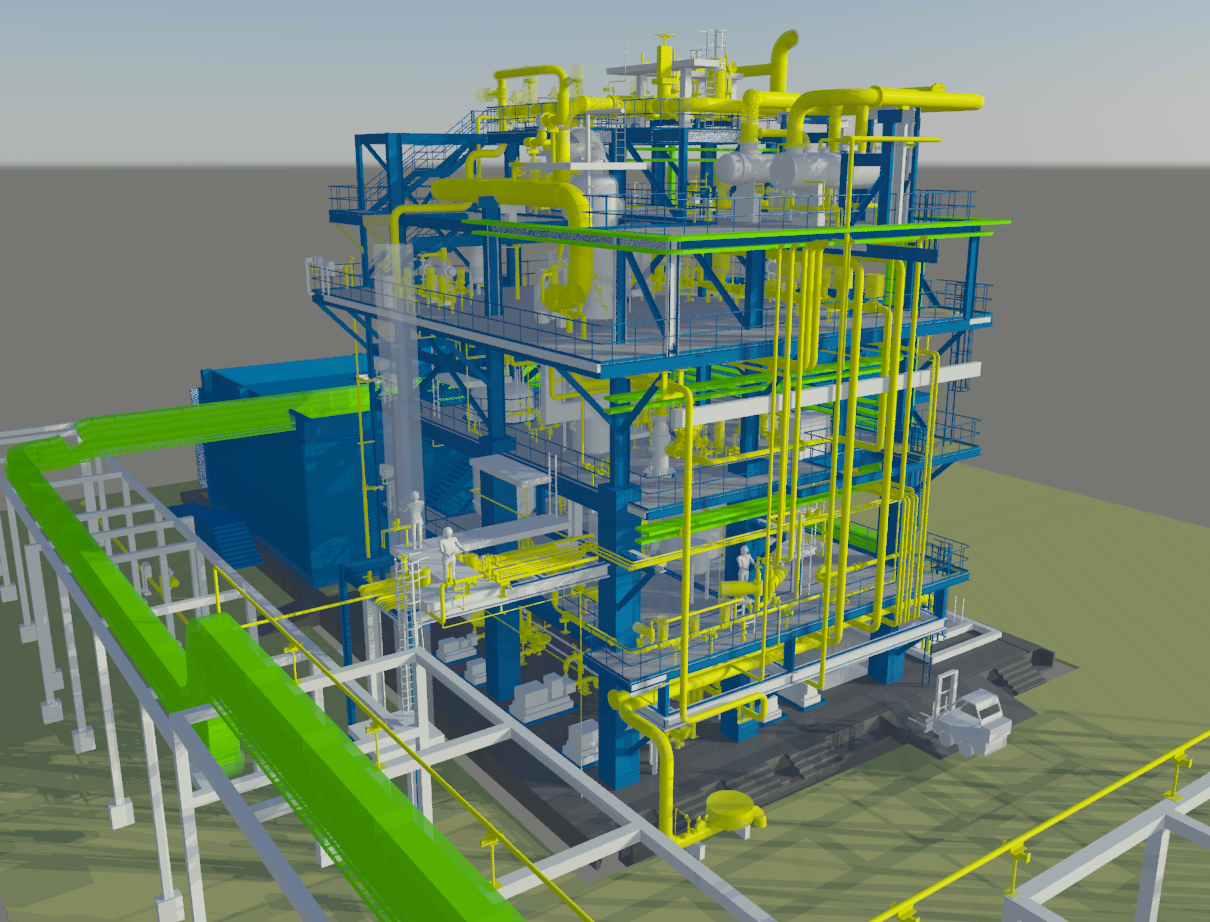

We support our customers at all design stages, from the initial concept stage through providing advanced technology and expertise to a detailed plan

Engineering & Contracting

Every project, whether a revamping or a new plant, requires in-depth knowledge, extensive skills, and proven experience to bring it to life

We stand by our clients by taking full responsibility as a contractor, offering a flexible approach that is customized to meet their specific needs during these delicate and critical phases of the project lifecycle. Through our subsidiary, Casale Project, and strategic partnerships with local engineering firms, we operate as a contractor. This versatility allows us to provide our customers with the personalized services and support they need to succeed. Our goal is to create efficient, sustainable solutions that contribute positively to the environment and our clients’ operational goals.

The key benefit: one single point of responsibility for the entire project, right from the early conception.

EP

engineering-procurement

EPC

engineering-procurement

construction

EPCM

engineering-procurement

construction-management

EP: We specialize in a broad range of engineering disciplines for the chemical industrial market, including process, mechanical, piping, electrical, and civil engineering, including structural steelwork and instrumentation, and control. We manage every phase of project documentation, from initial studies or investment plans through basic and extended basic engineering (FEED) to the detailed design stage. Our comprehensive design services include the procurement and delivery of equipment as outlined in the contract, catering to both onsite and offsite requirements.

EPC: We offer complete design services for turnkey projects, handling procurement, material supply, and overseeing construction and installation. Our approach ensures efficiency and excellence in meeting client specifications.

EPCM: Our services include design, equipment procurement, and supply, alongside managing and coordinating construction. We also focus on operator training and commissioning supervision, ensuring projects are completed to the highest standards, on time, and within budget.

Services

Services and products to improve reliability, extend operating life and optimise plant performance

Explore our specialized services in key technologies

Quality & Safety

At Casale, an unwavering commitment to quality and excellence has always been at the heart of our operations. Our commitment to safety for our people and the environment is equally paramount.

The focus on quality and HSE permeates our services and capabilities, ensuring that our customers benefit from a comprehensive and responsible approach to all aspects of their projects.

This is reflected in our HSE and Quality policies and our ISO certifications.

Innovation

R&D

We are driven by curiosity to transform the present and innovate future solutions

Discovery and innovation are our core purpose. This drives us to create products that prioritise environmental responsibility throughout their lifecycle. This strong commitment to innovation drives us to improve sustainability, increase capacity, improve efficiency, and reduce costs. We are always keen to explore customer needs and break new ground in industrial decarbonisation by exploring new application frontiers.

30

75

100

19

We handle every process step, from fundamental research to process development

Ready to dive into a concept or explore a new idea?

We are here to support you.

PARTNERSHIPs

We promote innovation with institutions and strategic partnership

At Casale, technological innovation is not a solo endeavour. We collaborate with prestigious international institutions, forge strategic partnerships with industry leaders, and engage with innovative start-ups. By combining our expertise with a diverse network, we drive innovation that propels us forward in the ever-evolving landscape of sustainable solutions.

35

6

4

11

4

3

Some of our Strategic and Long-Term Partners